Optima Condensing Boiler Catalog Download

Catalogue for All Capacities

Hydraulic Separator Catalog (Low Loss Header) Download

Low Loss Selection for Condensing Boiler Room

Packman General Catalogue Download

All Packman Product Catalogue

P 1

In the construction of Optima condensing boilers, stainless steel 316L tubes are used according to ASTM A269 standard, which exhibits very high resistance to heat and water acidity. This ensures prevention against corrosion in the condensation of flue gases.

Catalogue for All Capacities

Low Loss Selection for Condensing Boiler Room

All Packman Product Catalogue

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

All dimensions are in millimeters

xt format file

xt format file

xt format file

xt format file

xt format file

xt format file

xt format file

xt format file

In the construction of the Optima Condensing Boiler by Packman, all tests are conducted according to the prescribed process by the ANSI standard.

Additionally, all components related to the Pressure Part are in accordance with the comprehensive regulations of ASME codes.

Furthermore, all materials used in the heat exchanger are selected according to ASTM requirements.

In the construction of Optima condensing boilers, 300 series stainless steel (Austenitic Stainless Steel 3xx Series) is used, which, due to its nickel and chromium content, is a material resistant to the operating conditions of the boiler. Stainless Steel 316L is the only alloy resistant to acidic corrosion resulting from the operation of condensing boilers.

The main reason for the high efficiency of this boiler is the condensation created within the boiler. One of the few alloys resistant to this condensate at high temperatures is stainless steel alloy (316L Stainless Steel), which, due to its nickel and chromium content, is a material resistant to the operating conditions of the boiler.

The efficiency of Optima condensing boilers by Packman Company is based on a high-efficiency combustion system in HHV mode (depending on the relative humidity of the local air) of up to approximately 98.9%. This is according to Chapter 32 of the ASHRAE-HVAC System & Equipment Handbook, 2012 edition, which represents the highest level of efficiency for condensing boilers.

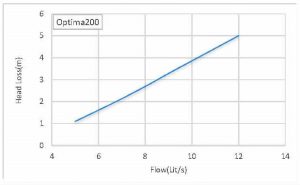

These boilers are designed vertically with a high water intake volume compared to other condensing boilers, ensuring minimal water pressure drop and combustion chamber even at maximum flow rates. This boiler can operate within the appropriate range for building design in terms of the temperature differential between supply and return, which may require the use of primary-secondary loop for system balance.